In today’s fast-paced construction environment, structural efficiency is more than a design goal—it’s a necessity. Engineers are increasingly challenged to deliver buildings that are cost-effective, code-compliant, and constructed within tight timelines, all while meeting high expectations for performance and sustainability. In that context, it’s no surprise that steel decking has emerged as a preferred solution. Versatile, durable, and lightweight, it’s helping engineers streamline workflows, reduce material loads, and meet structural demands without compromise.

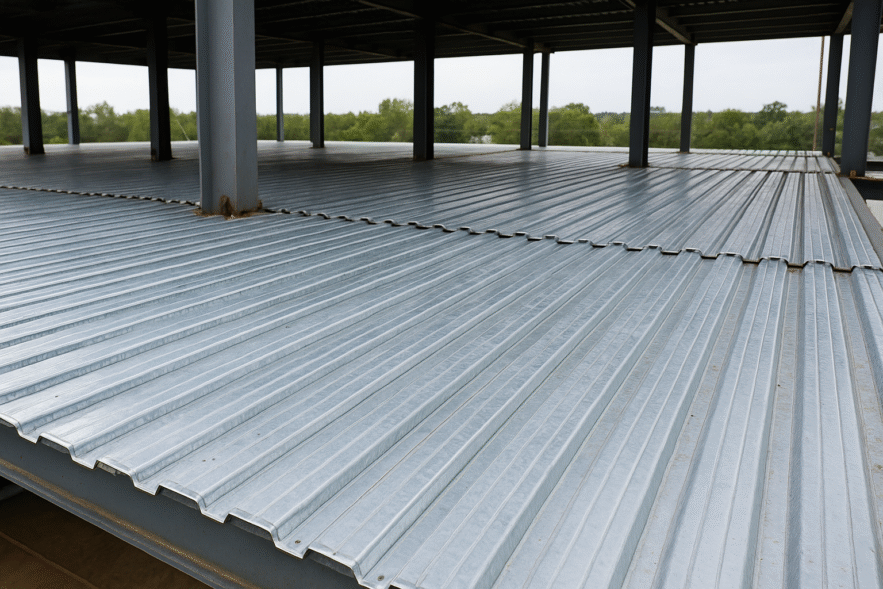

Steel decking isn’t a new concept, but its role has evolved significantly. Once viewed primarily as a formwork solution for concrete slabs, it’s now understood as a key structural component in both floor and roof assemblies. From mid-rise office buildings to industrial facilities and educational campuses, engineers are turning to this system as a way to optimize structural design and simplify coordination across trades.

Lightweight Strength That Improves the Entire Structure

A major reason engineers are embracing steel decking is its excellent strength-to-weight ratio. It supports concrete floor slabs or roof insulation while minimizing dead loads on the overall structure. This allows engineers to reduce the size and weight of supporting components—such as beams, girders, and columns—which translates into both material and cost savings.

Because these systems are cold-formed and manufactured with precision, they can be tailored to specific span and load requirements. Whether used as composite floor decking to work in tandem with concrete or as roof decking designed for diaphragm action, this approach helps avoid overengineering. That means more efficient designs, leaner framing systems, and better use of space and materials.

Faster Installation for Compressed Timelines

Steel decking is also popular for the speed it brings to construction. Traditional formwork is labor-intensive and slow, often becoming a bottleneck in multi-story projects. In contrast, steel deck arrives ready to install, serving as both the form and the working platform for crews. This dual function allows concrete placement and other trade work to begin much faster.

Installation can typically be done by a small crew with minimal equipment, and the panels are walkable shortly after placement. In a market where labor availability and scheduling are constant challenges, this efficiency provides a tangible advantage. On large commercial projects, cutting just a few days per floor adds up to weeks saved across the project—helping meet budget and delivery goals.

Flexibility to Support Complex Designs

Modern buildings are rarely one-size-fits-all, and engineers need materials that can flex to meet architectural and structural demands. Steel decking excels here as well. Available in a range of profiles, depths, and gauges, it allows engineers to design for long spans, heavy live loads, fire resistance, or acoustic control—depending on what the space requires.

These systems also integrate easily with fireproofing methods, sound-attenuation materials, and MEP routing. Whether working with composite beams, joist systems, or lateral load-resisting elements, steel decking offers compatibility across the board. This adaptability reduces design coordination issues and supports innovative, efficient layouts.

Durability That Lasts for Decades

Beyond its performance during construction, steel decking contributes to long-term building durability. It doesn’t warp, rot, or shrink like wood, and it holds up well in moisture-prone environments when properly protected. The structural stability it offers means fewer maintenance headaches and a longer service life—both of which reduce operational costs and improve overall building value.

In environments like schools, warehouses, and office buildings, this level of reliability matters. Owners expect systems that won’t need constant upkeep or premature replacement. For engineers focused on lifecycle performance, steel decking delivers confidence as well as capability.

Sustainability With Structural Value

In addition to strength and speed, today’s engineers are paying close attention to sustainability. Steel decking contributes here too. It is manufactured with recycled content and can be recycled again at the end of its use. Because of its high strength-to-weight efficiency, it helps reduce overall material consumption—a key benefit for green building certifications and energy-conscious projects.

By enabling smaller HVAC loads, less framing steel, and streamlined foundation requirements, it supports both embodied and operational carbon reduction. And in tandem with efficient installation and reduced construction waste, it plays a meaningful role in sustainability strategies that go beyond surface-level gestures.

Meeting Code and Supporting Innovation

Engineers must always ensure compliance with national codes and performance standards, and steel decking provides a well-documented, tested solution. Products manufactured in accordance with the Steel Deck Institute (SDI) specifications are supported by decades of research and industry acceptance. Engineers can confidently rely on known performance metrics, clear design guidance, and a wealth of available resources to support calculations and detailing.

This foundation makes it easier to innovate. With dependable material performance and proven system behavior, engineers can spend less time validating their base assumptions and more time pushing the boundaries of structural creativity.

The Structural System of the Future

The construction industry continues to demand more—from design, from materials, and from the engineers who bridge the two. In this high-stakes environment, systems that offer both performance and practicality rise to the top. Steel decking answers that call.

By combining efficiency, adaptability, and durability, it empowers engineers to create smarter, faster, and more resilient structures. It makes the math work, supports the vision, and delivers results—on the job site and across the full lifespan of the building.

It’s no longer just about selecting a decking material—it’s about choosing a structural strategy. And more often than not, that strategy is steel.